Airfoil Investment Castings Best of 2021

New casting facility for turbine blade and vane components. Complex Geometry Sand Castings.

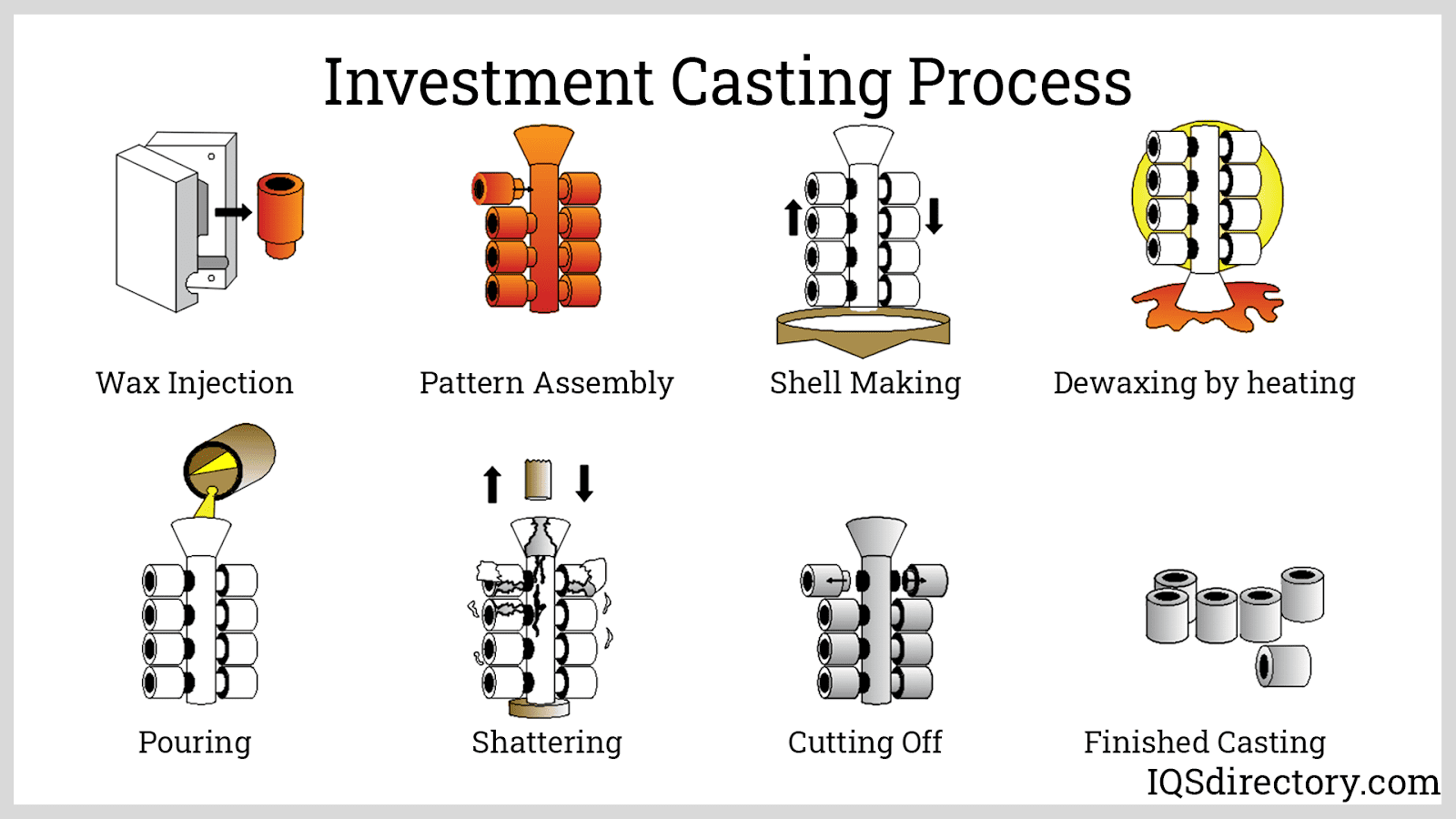

Metal Casting Processes 1 2 3 4 5

Pratt Whitney is committing to invest at least 650 million through 2027 to build an investment-casting plant in Asheville NC described as a 1 million sqft.

Airfoil investment castings. Siemens and Chromalloy Gas Turbine Corporation have entered a partnership to form a new joint venture called Advanced Airfoil Components. Pratt Whitney a division of Raytheon Technologies has announced plans to invest at least 650 million through to 2027 in a world-class turbine airfoil production facility in Asheville North Carolina. Company name Advanced Airfoil Components.

Triax Castings a state-of-the-art investment casting foundry providing Directionally Solidified Single Crystal Equiax Castings. Is the world leader in structural investment castings forged components and airfoil castings for aircraft engines and industrial gas turbines. Investment casting is still pushing its boundaries a great many advanced conceptual cooling designs are posing severe challenges.

Located in Le Creusot famous for 200 years as a centre of metallurgy and engineering Turbine Casting has developed a high level of competence based on the historically well-known lost-wax process. An investment casting method for a cast ceramic core 110 including an airfoil portion 116 shaped to define an inner surface 56 of an airfoil 52 of a vane segment 50 and an integral shell portion 122 having a backside-shaping surface 120 shaped to define a backside surface 68 of a shroud 62 of the vane segment. The facility equipment build-out is being done in stages and will be completed over the next four years.

The backsideshaping surface has a higher elevation 132 and a. The plant also will include onsite machining coating and finishing capabilities for airfoils. In 2015 it ranked 322nd overall and 9th in the aerospace.

Directionally solidifiedsingle crystal DSSC castings. Is an American industrial goods and metal fabrication company that manufactures investment castings forged components and airfoil castings for use in the aerospace industrial gas turbine and defense industriesIn 2009 it ranked 362nd on the Fortune 500 list and 11th in the aerospace and defense industry. Presently the Hampton foundry.

Turbine Casting is Specialist Supplier of Blades and Vanes for Gas Turbines. Says it plans to invest at least 650 million through 2027 in a world-class turbine airfoil production facility in Asheville North Carolina. We are constantly.

And since performance and fuel efficiency both increase as the gas temperature inside the engine increases – this has created a need for complex aerodynamic turbine airfoils that operate at higher service temperatures. Shipment of initial components in 2018. Traditional 3D-printed core production.

The new 1000000ft² facility will house an advanced casting foundry for the production of turbine airfoils as well as conduct machining. The combination of the digital fast pre-products with high end casting capability is unmatched in the. Investment casting has been used to manufacture weapons jewellery and art castings during the ancient civilization.

Alcoa Howmet launched a 25-million expansion of its Hampton VA investment casting foundry to produce a new range of aerospace parts adding another manufacturing line and modifying some current equipment to cast airfoil blades for jet engines. A method and casting core for forming a landing for welding a baffle inserted into an airfoil are disclosed wherein the baffle landing of the blade or vane is formed in investment casting by the casting core rather than by wax reducing tolerances and variability in the location of the baffle inserted into the cooling cavity of airfoil when the baffle is welded to the baffle landing. The latest in technology in the investment casting process produces high quality mechanical component parts cost effectively and on time.

PCC Airfoils manufactures complex highly technical investment castings Current aerospace trends have placed a premium on engine performance and fuel efficiency. The Advanced Airfoil Components casting facility is 210000 square feet and enables production of the entire range of blades and vanes for Siemens Energys gas turbine fleet including the newest 9000HL. The stand-alone manufacturing plant.

Flowcastings is then transferring these products into high end investment castings non-compromised in their directional solidified or single crystal grain based physical properties. USD130 million investment will create up to 350 new jobs. The project also signifies a product line expansion of sorts.

Today its applications include jewelleryart castings turbine blades and many more industrialscientific components. The present paper reviews various investigations made by researchers in different stages of investment casting. Figure 4 schematically illustrates the five conventional cooling philosophies that are produced today with investment casting.

Leading manufacturers such as Airbus Boeing GE Rolls-Royce and many more rely on us for critical airframe engine power generation and general industrial components. Casting Division Chandler AZ Our staff with 100 years of experience in investment casting of turbine airfoils ensures on-time deliveries of high quality precision castings. Pratt Whitney plans multi-year multi-million investment in facility for turbine airfoil production castings November 30 2020 Pratt Whitney East Hartford Connecticut a division of Raytheon Technologies Corp.

Advanced casting foundry for turbine airfoils. PCC Airfoils manufactures complex highly technical investment castings for turbine engine applications. Equiaxed structural and airfoil castings.

Infinair Highly Efficient Inline Vane Axial Fan Yfiam Axial Inline Fan Inline

Turbine Casting Investment Casting Specialist For Igt Blades And Vanes

A Selection Of Investment Cast Parts The Process Is Used When Parts Are Thought To Be Too Complex To Stainless Steel Casting Investment Casting Manufacturing

Infinair Highly Efficient Inline Vane Axial Fan Yfiam Inline Fan Axial Inline

Scheme Of The Investment Casting Process Of The Aircraft Engines Components Download Scientific Diagram

Metal Casting Unit 1 Unit 2 Asst Prof

Pin By Cslcjf On Nasa Jet Engine Aircraft Engine Engineering

Some Of The Aerospace Investment Castings And Corresponding Alloys Download Scientific Diagram

Previously Asked Questions Investment Casting Institute Montvale Nj

Lost Wax Casting What Is It How Does It Work Parts Metal

Metal Casting Processes 1 2 3 4 5

Precision Casting Parts Investment Casting Is One Of The Oldest Manufacturing Processes Investment Casting Can Make U Investment Casting It Cast Investing

Infinair Axial Fan Inline Fan Inline Axial Fan Yfiam General Air Supply And Exhaust Explosion Proof Air Supply And Exhaust Posi Axial Inline Fan Inline

Chapter 11 Metal Casting Processes Sand Casting Other

Turbine Casting Investment Casting Specialist For Igt Blades And Vanes

Dbt 206 Foundry Technology Lecture 6 Molding Casting

Metal Casting Unit 1 Unit 2 Asst Prof

Some Of The Aerospace Investment Castings And Corresponding Alloys Download Scientific Diagram

Schematic Drawing Of Investment Casting Of Sx Turbine Blades Download Scientific Diagram

Post a Comment for "Airfoil Investment Castings Best of 2021"